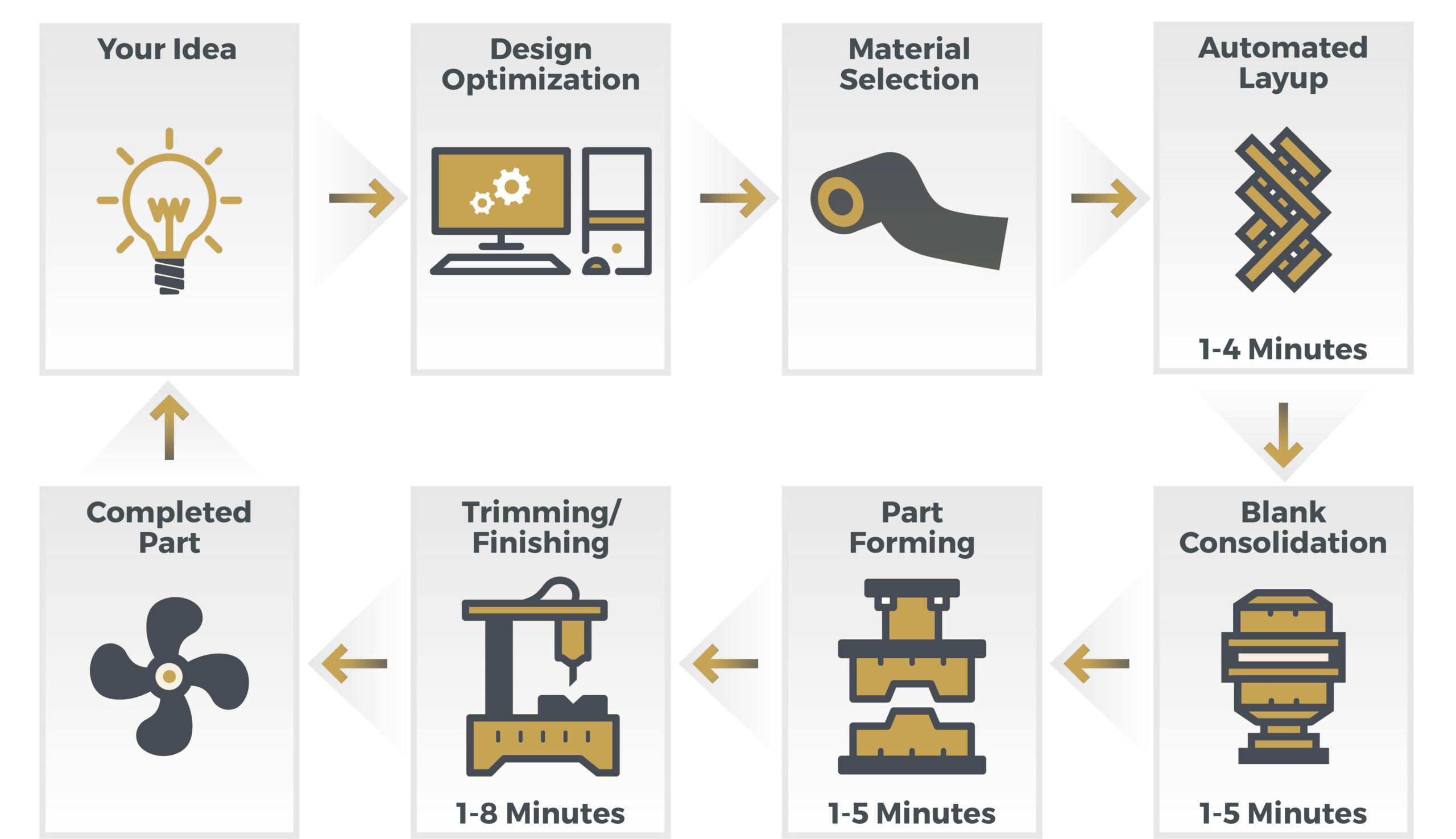

3D FORM™ process.

Our award-winning 3D FORM™ process embraces the inherent processability advantages of thermoplastic composite materials, and delivers high volume, complex structural components affordably.

As thermoplastics are melted and thermoformed rather than cured, they can be processed into final parts in minutes. While the foundation of this process has been well developed in the industry over time, Oribi has built on this foundation with proprietary, high speed tailored layup, heating and forming methods, orchestrated by automation and robotics. 3D FORM™ ultimately delivers high performance, high-quality, lightweight parts affordably, and in high volumes.

3D FORM™ is compatible with a wide range of fiber and polymer combinations, allowing us to create highly tailored structures optimized to your exact performance requirements, while reducing or eliminating unnecessary waste, weight, and cost.

The advantages of 3D FORM™ can be enhanced with our Oribi Over Mold process, further providing you with design freedom for fit, form, function and cosmetic requirements.