Designing and producing advanced composites.

At Oribi, our passion is to deliver on the promise of advanced thermoplastic materials for our customers. Our in-house engineering team will apply their decades of composite material knowledge to your designs, identifying opportunities to optimize the performance and reduce the weight of your components.

From material selection to full-rate production, we tailor our process to meet your exact program specification without the high price tag typically associated with composite materials.

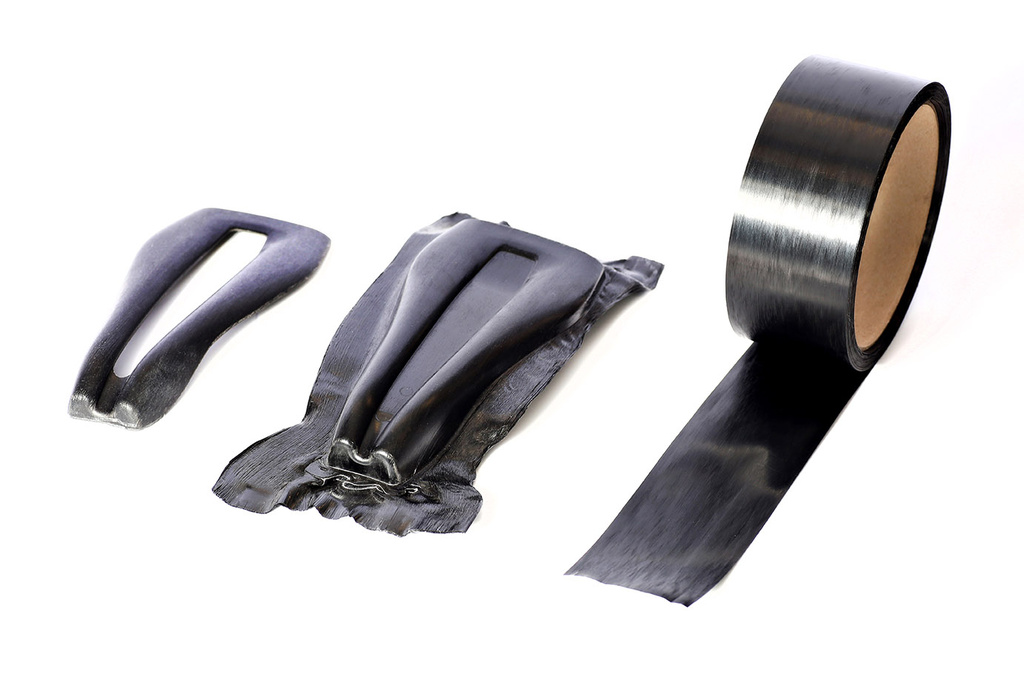

Oribi 3D Form™

Our award-winning 3D FORM™ process embraces the inherent processability advantages of thermoplastic composite materials Read more…

Oribi Spin™

Built on our proprietary 3D FORM™ technology, Oribi SPIN™ is the industry’s first circular production platform for continuous Read more…

Over Mold

Oribi Over Mold unites structural performance with design freedom when combined then combined with Oribi 3D FORM™ Read more…

How we work with you.

Project brief.

We will work with you to understand your project objectives, including part requirements, key mechanical and structural performance objectives, target unit cost, production rate plan, and timelines.

Feasibility study.

Our team of engineers are composite design experts. We have converted thousands of parts from traditional materials to advanced composites in a wide range of industries across the world. Our team will work with you to develop a design using thermoplastic composite materials to provide the most value to your program, and to help you achieve your project goals.

Design optimization and simulation.

We will apply our expertise in composite material design and production optimization for your needs, enabling cost-effective, high volume manufacturing of stronger, lighter, and tougher components. Key elements include:

- Tooling design and development

- Advanced 3D design and finite element analysis simulation as required

- Material selection and laminate design, including optimizing ply count and ply orientation, fiber type, and resin chemistry

- Fabrication method selection within our 3D FORM™, SPIN™or Over Mold processes, or development of new processes to meet your specific program requirements.

Oribi’s wide range of processes and vertical integration from material selection through production enables us to control costs and maintain quality throughout the process. We do not push you to adopt unnecessarily high-cost materials or processes; rather, we work with you to meet your cost and rate objectives to maximize the success of your product.

Proof of concept evaluation.

We start every program with a well-developed proof of concept and component qualification plan. We work in partnership with our customers to prototype, test, and qualify parts to validate component design and to optimize performance before transitioning to full rate production.

Full-scale production.

Following prototyping, testing and qualification, we transition to full-scale manufacturing to meet your production rate demands. Oribi’s practical approach to production scale up enables us to meet very aggressive production rate volumes and timelines in a matter of weeks for most programs.

All production takes place within our US-based 50,000 sq. ft facility, from part layup through forming, trimming, finishing and final inspection. We also offer our customers assembly services internally, or through our partner companies within Re:Build Manufacturing.